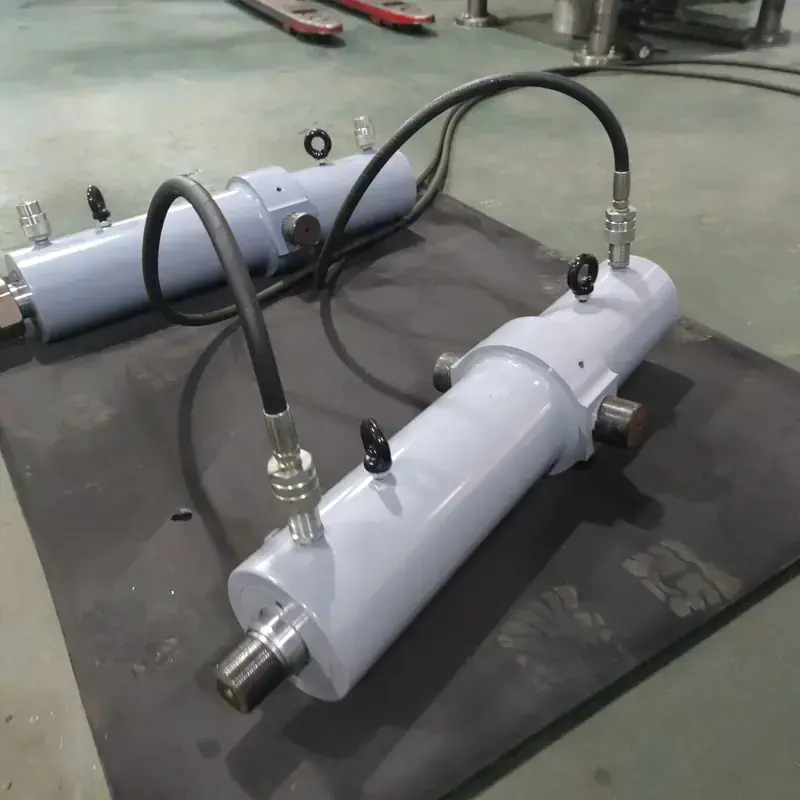

BRP 10/30/50 ton 151/152/155 mm Pull Hydraulic Cylinder

-

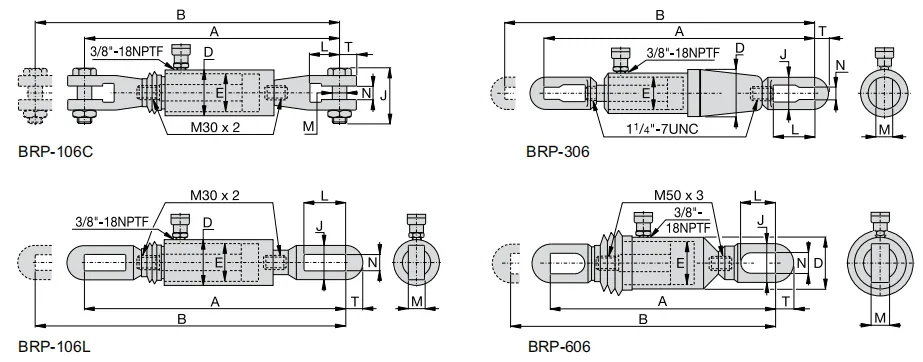

Model:BRP106C/BRP106L/BRP306/BRP606

Capacity:10/30/50 ton/105/326/505 KN

Stroke:151/152/155 mm/5.9/6/6.1 in

Maximum Operating Pressure:700 bar/10000 PSI

Weight:15.9-53.5 kg/35.1-118 lbs

Oil Capacity:227-1096 cm³/13.9-67 in³

Material:Steel

Brand Name:Replacement Enerpac's BRP106C/BRP106L/BRP306/BRP606

SKU:AXT-15-00631

- BRP106C, 10 Ton Capacity, 151mm Stroke, Pull Hydraulic CylinderBRP606, 60 Ton Capacity, 152mm Stroke, Pull Hydraulic CylinderBRP306, 30 Ton Capacity, 155mm Stroke, Pull Hydraulic CylinderBRP106L, 10 Ton Capacity, 151mm Stroke, Pull Hydraulic CylinderBRC106, 10 Ton Capacity, 151mm Stroke, Pull Hydraulic CylinderBRC46, 5 Ton Capacity, 140mm Stroke, Pull Hydraulic CylinderBRC25, 2.5 Ton Capacity, 127mm Stroke, Pull Hydraulic CylinderBRP 10/30/50 ton 151/152/155 mm Pull Hydraulic CylinderBRC 2.5/5/10 Ton 127/140/151 mm Pull Hydraulic Cylinder

Description

Model:BRP106C/BRP106L/BRP306/BRP606

Product Line: Industrial Tools

Type: Hydraulic Cylinder Ram, Hydraulic Jacks

Customizable with special requirement

- High strength alloy steel construction

- Plunger blow-out protection to prevent rod over-extension

- Hard chrome-plated plunger for long life

- Replaceable links on BRP-models

- Baked enamel finish for increased corrosion resistance

- CR-400 coupler and dust cap included on all models

- Plunger wiper reduces contamination,extending cylinder life

- Single-acting, spring return

TO lifta load bearing mast into place,BRP-series cylinders were used to tension the supporting cables.

Our BRC Pull Hydraulic Cylinder product in the same series was also employed to tension the supporting cables, ensuring precise lifting of the load-bearing mast into place.

Series Comparison

| Model Number | Cylinder Capacity | Stroke | Cyl. Effect. Area | Oil Cap. | Coll. Height | Ext. Height | Outside Dia. | Cyl. Bore Dia. | Link Height | Link Opening | Link Thickness | Link Width | Slot to Link End | Weight |

| ton (kN) | (mm) | (cm²) | (cm³) | A (mm) | B (mm) | D (mm) | E (mm) | J (mm) | L (mm) | M (mm) | N (mm) | T (mm) | ||

| BRP106C | 10 (105) | 151 | 15 | 227 | 587 | 738 | 85 | 54.1 | 119 | 62 | 30 | 35 | 32 | 15.9 |

| BRP106L | 10 (105) | 151 | 15 | 227 | 541 | 692 | 85 | 54.1 | 67 | 115 | 22 | 30 | 32 | 13.2 |

| BRP306 | 30 (326) | 155 | 46.6 | 722 | 1085 | 1240 | 136 | 88.9 | 114 | 145 | 35 | 39 | 50 | 48.1 |

| BRP606 | 50 (505) | 152 | 72.1 | 1096 | 719 | 871 | 140 | 110 | 130 | 149 | 39 | 50 | 70 | 53.5 |

*Available as set, see note on previous page. NOTE: BRP-106C, BRP-106L and BRP-606 are fitted with rubber bellows for rod protection.

FAQs

Q: What should be considered in the maintenance and servicing of a Pull Hydraulic Cylinder?

A: Maintenance and servicing of a Pull Hydraulic Cylinder should focus on:

Regularly inspecting seals to prevent leaks

Ensuring hydraulic oil cleanliness to avoid contamination

Checking the cylinder surface for rust and mechanical damage

Regularly lubricating moving parts to ensure smooth operation

Following the manufacturer's recommendations for regular maintenance and inspections

Q: What is the main difference between a Pull Hydraulic Cylinder and a Push Hydraulic Cylinder?

A: The main difference between a Pull Hydraulic Cylinder and a Push Hydraulic Cylinder lies in the direction of force they generate. A Pull Hydraulic Cylinder is designed to produce pulling force, retracting the load towards the cylinder body, while a Push Hydraulic Cylinder is designed to generate pushing force, extending the load away from the cylinder body. The choice of which type to use depends on the specific application requirements.

Comment

PROVIDING EXCELLENT SOLUTIONS BY Axion™

You're fortunate to have found a manufacturer, supplier, and factory in China, Ningbo Axion Machinery Co., Ltd.,

that offers a diverse selection, reasonable price,fast delivery, and products of comparable quality and performance to Enerpac's BRP 10/30/50 ton 151/152/155 mm Pull Hydraulic Cylinder.

Please send an email immediately with information regarding the "BRP 10/30/50 ton 151/152/155 mm Pull Hydraulic Cylinder" You will receive our response within 24 hours.